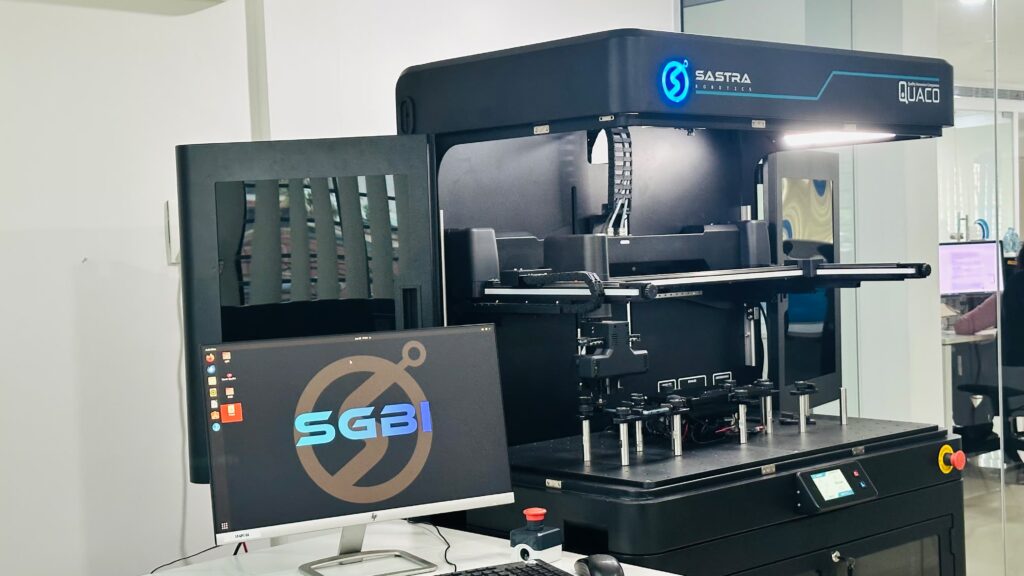

Quaco Pro D

The perfect blend of speed, accuracy, and reliability for high-demand testing environments.

Quaco Pro D, a state-of-the-art  industrial robot designed for businesses ,seeking a powerful, precise, and

industrial robot designed for businesses ,seeking a powerful, precise, and  versatile solution for automating their testing workflows. Built for

versatile solution for automating their testing workflows. Built for  high-speed operations, Quaco Pro D guarantees consistent results and

high-speed operations, Quaco Pro D guarantees consistent results and  seamless integration into your production line.

seamless integration into your production line.

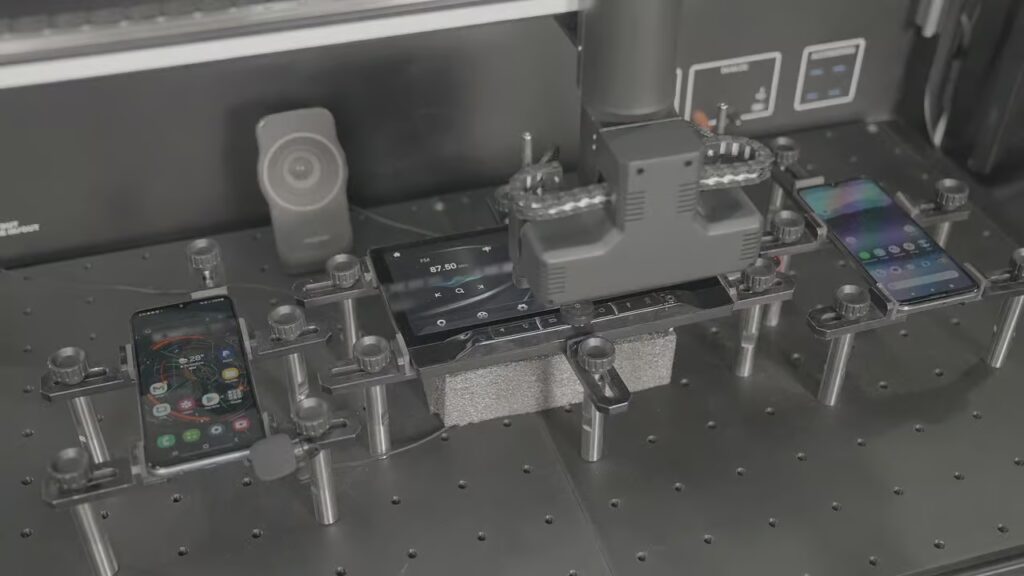

QUACO Pro-D is built using a high-speed cartesian robotic arm with two dexterous fingers, enabling both single and dual-finger gestures. The fingers, equipped with force sensors, navigate the X, Y, and Z axes, interacting with touchscreens, buttons, and switches.

Intelligent Vision System

The vision system offers a flexible testing environment by combining intrusive and non-intrusive methods. Screen grabbers and strategically placed cameras capture device behavior, while the built-in finger module camera simplifies API generation and test script creation. Global camera positions enable remote operations, surveillance, and bug detection.

Onboard computer & Cloud Connectivity

The QUACO Pro-D's edge computing capabilities enable the testing infrastructure to decouple with complex computation and vision algorithms. Test executions can be controlled over the cloud, where the vision-based test executions are processed locally and provide the test results.

Multi-purpose test rig with storage

QUACO Pro-D provides a sophisticated test rig with numerous built-in features to meet current and future test automation requirements. These features include an API- controllable power supply, safety indicators, an HMI display, accessory expansion ports, programmable GPIO ports, and more.

What Makes Quaco Pro D Stand Out?

Experience Seamless Testing with Quaco Pro D

Codeless Automation

Quaco Pro-D automates test case creation and scenario generation with AI/ML-powered vision-based software.

In-built Computer Vision

Offers trained vision packages and multiple camera options for enhanced OCR and pattern matching accuracy.

High-speed & force-sensing robotic fingers

Simulates realistic human touch with precise control over force, speed, and duration.

Active multi-fingers

Supports diverse single and multi-finger gestures on touchscreens and hard buttons, with replaceable fingertips.

Edge computing & Cloud connectivity

Onboard computers process vision and test data, faster computation, secure data storage, cloud integration and remote operation.

Smart Test Rig

Equipped with safety features to protect both DUT and users.

Large Workspace

A large workspace with simple mounting options accommodates multiple test devices with various configurations.

Accessory Expansion Ports & API Controllable GPIO Ports

Easily integrates additional accessories and peripherals.

In-built HMI

Provides real-time updates, alerts, and maintenance notifications.

API Controllable DUT power supply

Standard 12V/2A and 5V/4A power supply for DUT with customizable options.

Automatic API creation

Automatically generates low-level and high-level APIs for seamless integration with test automation frameworks and CI/CD pipelines.

Safety Modules

Integrated emergency switches, status indicators, door state detection, and alerts for enhanced safety.

Robotic Finger Actions

Complete Automated Robotic Testing with our advanced robotic components.

Tap

Swipe

Hold

Flick

Hover

Press

Drag

Multi-Tap

Rotate

Sign

Tap

Drag

Pinch

Zoom

Rotate

Replicating Human actions. QUACO PRO-D is designed to mimic human finger actions with incredible precision. From simple taps to complex gestures

The robot can effortlessly perform a wide range of interactions. This versatility empowers you to automate intricate test scenarios that were once thought impossible.

With its extensive range of motion and advanced control systems, QUACO PRO-D can adapt to virtually any device and user interface.

With QUACO PRO-D, you can simulate a multitude of human actions, including accurate single and double taps on touchscreens and buttons, Perform smooth swiping gestures, Reproduce quick and precise flicking motions etc.

This makes it an indispensable tool for testing a wide variety of products, from smartphones and tablets to automotive infotainment systems and industrial control panels.

Vision System & Camera Modules

Advanced Vision Systems for Precise Testing & validation.

High-Resolution Imaging for Detailed Test Monitoring

The vision system primarily relies on the live camera feed from the built-in camera on the finger module as its primary input. QUACO Teach Studio and other software suites use these vision inputs for calibration and marking vision references such as screen positions, icons, buttons, indication lights, OCR fields, etc.

It uses an industrial camera with a specification of 13 Megapixels, capable of recording videos at 30 frames per second and offering 4 K resolution. The local camera provides users with a closer view of the screen activities, facilitating easy and better test script generation and execution.

Capture the Big Picture: Comprehensive Test Bench Overview

The global camera module provides a comprehensive view of the test setup, capturing the entire active field of view from above. It allows users to quickly navigate from one corner of the test bench to another, especially during remote operations, saving valuable time.

Users can select various combinations of cameras and lenses. SGBI’s technical team can assist in choosing the correct combination based on the customer’s test requirements. The module is mounted on a manual positioning x-y rail with a manual lock, offering flexibility.

Ensuring Remote Visibility and Accountability: The Surveillance Camera Module

The surveillance camera module aims to deliver a close view of the test device during remote operations, ensuring no interference. Its position and camera viewing angle can be easily adjusted using manual thumb screws.

This near-field camera will be essential in the future for capturing video evidence during bug log reporting and will be crucial for ensuring smooth remote monitoring and operations.

High-Speed Imaging: A Powerful Tool for Optimizing Device Performance and User Experience

We offer optional high-frame-rate industrial camera modules and lens systems specifically designed for this position. These custom modules are ideal for capturing frame loss or calculating response time.

The optional High speed industrial cameras can be used for evaluating the responsiveness of devices to user inputs, ensuring that your device’s performance meets the required standards, providing critical data for performance optimization and bug fixes.

Robotic Testing Accessories & Enhancements

Expanding Your Testing Capabilities: Essential Accessories for QUACO PRO-D

Interfaces & Connections

Expanding Your Testing Capabilities: Versatile Connectivity Options

Accessory Expansion Port

The accessory expansion port enhances test coverage by adding extra test support hardware. These support hardware include multiple mechatronics systems, cameras, screen grabbers, etc., incorporated into the testing platform.

We provide a range of compatible accessories across various industries, including point of sale (POS), smartphone testing, automotive testing, and consumer electronics testing.

- Versatile Connectivity – The Accessory Expansion Port offers plug-and-play compatibility for all SGBI accessories. Users can effortlessly access and configure these accessories directly from the QUACO studio.

- API Controllability – All the accessories connected to these ports can be controlled using the QUACO Studio software or through a specific API integrated with the host system.

- Custom Accessory compatibility – SGBI supports designing custom accessories for your testing needs. Like standard accessories, users can incorporate these into their test bench by plug-and-play.

Programmable GPIO Ports

In addition to the accessory expansion port, we also provide programmable General-Purpose Input-Output (GPIO) ports with the rig. This includes a 4-port GPIO with two inputs and two outputs(OUT1 is dedicated for E-Stop trigger), compatible with 3V to 12V, located near the auxiliary E-stop port.

These GPIO ports are highly versatile and can be configured to suit various test requirements. The function of GPIO pins can be set up via software by tagging different events with these GPIOs. So whenever these configured events occur, the configured GPIO will change the state accordingly.

All these GPIOs can be tagged to a set of events associated with the robotic platform, enabling them to communicate with the DUT itself or any test-associated hardware to trigger a specific functionality during the test execution. This will be useful in situations like handling exceptions in the testing routine, such as hard resetting the DUT or restarting the DUT etc.

The Gallery

Glimpse the Future of Automated Testing: QUACO PRO-D in Action

Got a question?

No problem.

Have a question about QUACO PRO-D or need assistance? Our team of experts is ready to help.

Frequently Asked Questions

How do we test DUTs with different heights?

The QUACO Pro D robot is designed with adjustable height functionality to accommodate DUTs of varying heights. There are two methods to adjust the robot’s height:

Via the Front HMI Display Unit:

- Navigate to Menu > Height Adjustment on the display unit.

- Use the right-side navigation buttons to set the desired height (displayed in millimeters).

- The maximum height adjustment is 275 mm from the test bench level.

Using the Quaco Studio Software:

- During HAPI creation or test execution, the height can be configured through the API triggers.

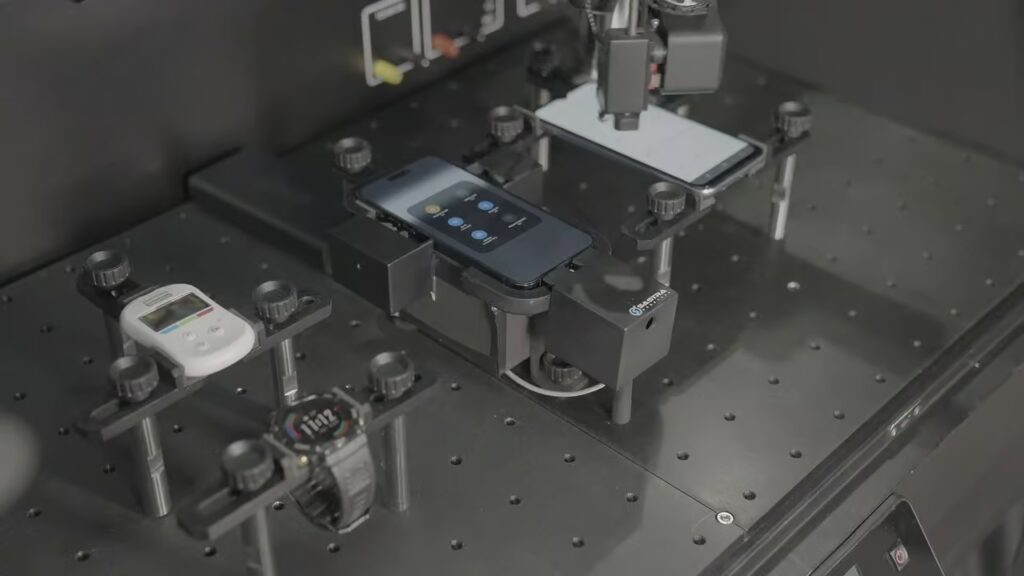

How can I mount DUTs (Devices Under Test) to the robot?

To mount a DUT on the rig, you can use various types of fixtures depending on the DUT’s form factor. QUACO includes a standard package of generic fixtures compatible with most DUTs across different industries.

What are generic fixtures, and how do they work?

Generic fixtures are versatile mounting components provided with QUACO. They function like a Lego-style setup, allowing quick and straightforward DUT assembly.

What if my DUT has a very complex form factor?

For devices with complex form factors, SGBI offers custom fixtures designed to fit your specific needs. For more details, please contact support@sgbi.us.